Optimising Manufacturing through smarter Processes

Industry 4.0 is converging AI, Cloud, Analytics, ML, Edge Computing, and a deluge of IoT data to empower manufacturing & logistics. It’s complex, but we have you covered.

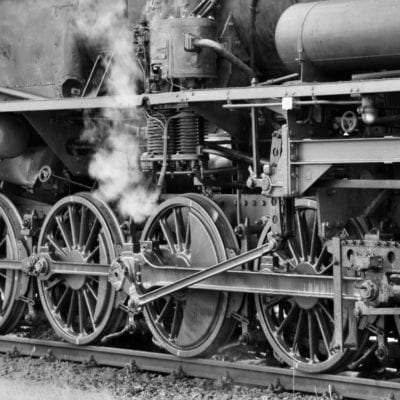

Industry 1.0

1784

Industry 2.0

1870

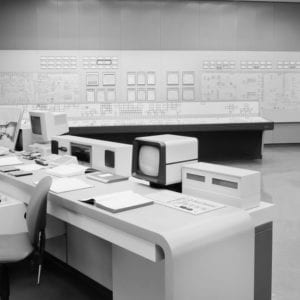

Industry 3.0

1969

Industry 4.0

Today

Industry 4.0 Opportunities

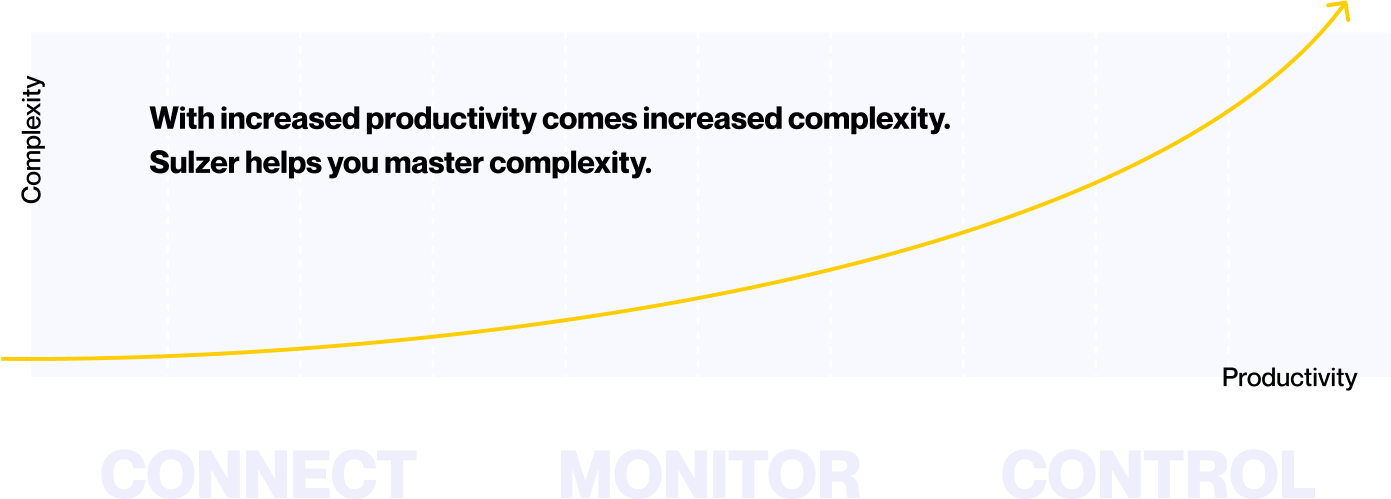

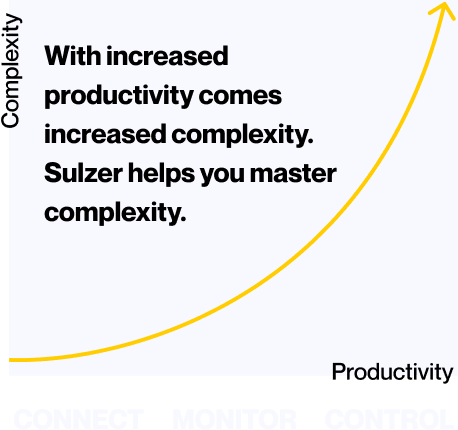

Industry 4.0 promises higher productivity, efficiency, and profitability by intelligently connecting and monitoring devices, machines, and workers—sending invaluable data streams to decision makers in real-time.

Are you reaping the rewards of Industry 4.0 driven processes?

Additional value creation potential in the automotive and engineering industries by 2025 through Industry 4.0.

Potential increase in productivity by first wave of IIoT adopters and drop in maintenance costs.

Return on Investment (ROI) due to sizable inventory reduction and increase in productivity.

Technologies Transforming Manufacturing

Sulzer is bringing the visions of Industry 4.0—everything connected and everything as a real-time data source—to it’s customers.

By creating adaptable processes within Smart Factory we can help you maximize production throughput, create a smarter workforce, and vastly improve the economics of your business. Here are the building blocks we can help you integrate with your manufacturing processes & workflows.

Building a Smarter Factory

The benefits of Industry 4.0 and Smart Factory are compelling. Let Sulzer help guide your journey.

Systems Integration

The average factory generates 1 Terabyte of data per day but evaluates less than 1%. Sulzer integrates all industry 4.0 data with enterprise ERP, BI, CRM, and Ticketing Systems to maximize usage and value, end-to-end.

Big Data & Analytics

The true value of data is reached when made accessible in its entirety for evaluation from anywhere in the enterprise. Sulzer combines data from production machines, enterprise systems, and supply chains and embeds it within the analytics process to create actionable insights.

AI – IIoT & Edge Computing

IIoT and AI are a perfect fit: they both need compute-intensive technology to perform from the DC to the edge. Sulzer efficiently integrates AI, IIoT, & edge computing with manufacturing processes to derive the high quality operational insights.

Cyber & Data Decurity

Industry 4.0 delivers undeniable value but it brings with it a hoard of new cybersecurity threats. Sulzer protects industrial systems, communications, and IIoT devices from potential cyber attacks, for secure and reliable operations.

Minimize operational downtime

Using AI, NLP, and ML, our solutions tap into vast quantities of unstructured data to intelligently manage performance and fault alarms. We predict bottlenecks, potential faults, and performance inefficiencies.

Sulzer powered Incident Management Solutions for Industry 4.0 reduce planned an unplanned downtime — always getting better.

Performance & Fault Monitoring

Industry 4.0 News

Utilizing hidden data: creating an ontology in SAP HANA Cloud

Demonstrating the feasibility of creating an ontology and a knowledge graph based on simple product data and implement it…

SAP BW/4HANA: The Grey Panther of Data Warehousing

Discover why SAP BW/4HANA remains relevant with strengths in metadata management, governance, and automation.

When you shouldn’t use generative AI (GenAI)

Generative AI promises groundbreaking innovations, but it is not always the best solution. A report by Gartner shows when…