EDI (Electronic Data Interchange) is a key technology for increasing efficiency in communication between companies. Sophisticated monitoring of EDI processes is essential in order to improve data quality and ensure long-term cost efficiency.

We would like to use specific practical examples to illustrate how companies have successfully achieved improvements through targeted EDI monitoring.

Practical example from the automotive industry: improving delivery note quality

A customer from the automotive sector initially had a delivery note quality of around 86%. As the production chain in this industry is meticulously timed and only low stock levels are available, punctuality and completeness of the Advanced Shipping Notifications (ASN) are crucial.

Incorrect or delayed ASN data leads to manual effort, higher costs and the risk of incorrect bookings.

Through targeted quality improvement measures based on structured EDI monitoring and systematic feedback to suppliers, we were able to increase delivery note quality to almost 98%. These improvements were achieved with the help of a three-stage quality assurance model for suppliers:

- Error identification and feedback: Automated systems identified errors and informed suppliers in detail about their nature.

- Voluntary training for error prevention: Voluntary training was offered for repeated errors in order to eliminate the causes and prevent future errors.

- Mandatory training for persistent problems: If the same errors continued to occur, the suppliers were obliged to pay for training. This helped to ensure high data quality in the long term and reduce the burden on internal processes.

This approach not only led to a reduction in manual correction work, but also enabled improved production planning and optimization of the entire supply chain.

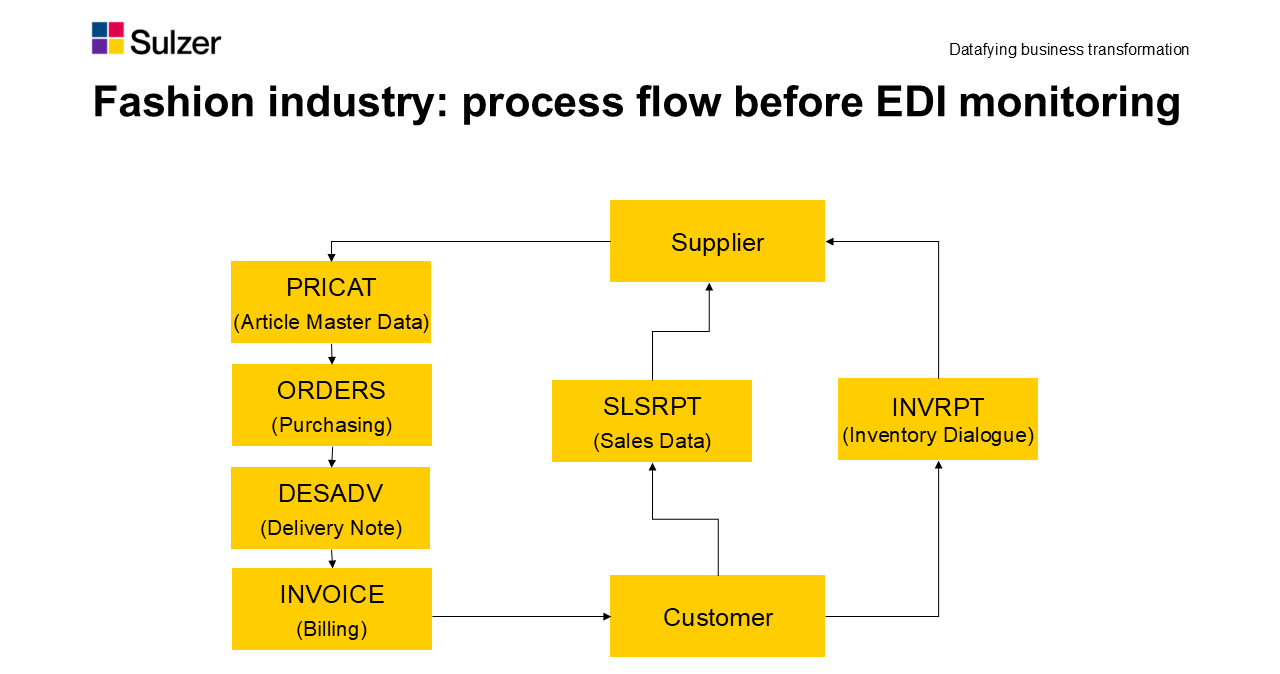

Case study from the fashion industry: Effective error analysis after ERP conversion

Another example shows how EDI monitoring can also help optimize processes in other industries. A customer from the fashion industry carried out an ERP conversion, which resulted in an increased workload for EDI support. The causes were initially unclear: the ERP team blamed the EDI systems, while the EDI team blamed the ERP system.

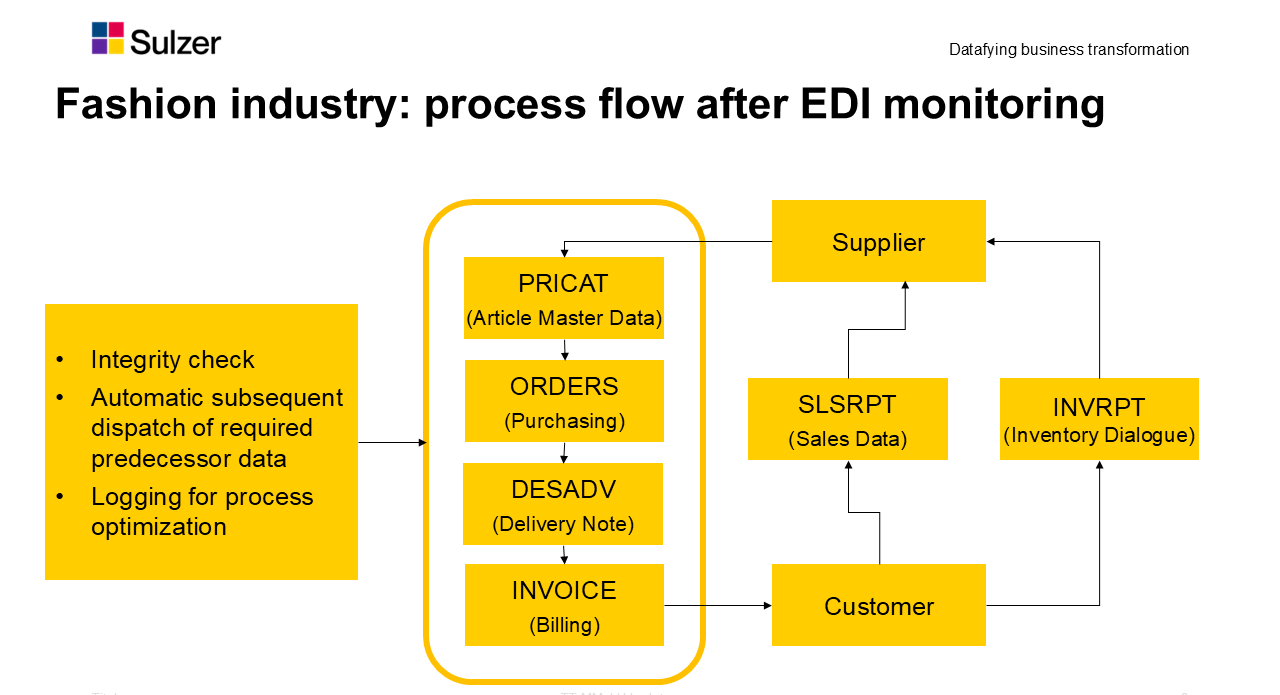

Only after the introduction of a comprehensive EDI monitoring system was it possible to identify and eliminate gaps and weak points in the order and shipment process.

In addition, functionalities such as the automated subsequent shipment of price lists (PRICAT), the monitoring of the entire process chain and the triggering of alerts in the event of process disruptions were integrated. This led to more efficient order processing and a significant reduction in errors.

Future prospects – integration of IoT and AI

The future of EDI processes lies in the combination with technologies such as the Internet of Things (IoT) and artificial intelligence (AI). These technologies make it possible to work even more precisely and efficiently and to realize further optimizations:

Real-time monitoring through IoT

By integrating IoT sensors, deliveries can be tracked in real time and production processes monitored. This enables more precise planning and reduces delays that could otherwise have a negative impact on production.

Predictive analytics and proactive measures

AI-supported predictive analytics offers the opportunity to identify potential problems at an early stage before they arise. For example, delivery delays or machine malfunctions can be predicted so that measures can be taken in good time.

Automated error detection and correction

Machine learning algorithms automatically detect errors in EDI documents and generate correction suggestions. This reduces manual effort and significantly increases the accuracy of the data.

In addition, monitoring enables continuous monitoring of supplier performance in order to select and promote the best partners.

Are you interested?

Would you like to find out how you can use state-of-the-art technology to make your EDI processes more efficient and future-proof your supply chain? We will be happy to support you in developing the right solutions for your requirements. Contact us to discuss the next steps together and make your processes fit for the future. Together, we can increase the efficiency of your business processes, reduce costs and set new standards in terms of data quality and automation.